Grant agreement ID: 821000

DOI

Project closed

EC signature date3 May 2019

Start date1 June 2019

End date30 November 2022

Project Context & Objectives

Mineral wool (insulation) represents a significant environmental challenge. Although it makes up only 0.2% of CDW by weight, its low density means it occupies a disproportionately large volume in landfills, where costs are expected to rise above €100/t.

- The “Wasterial” Goal: Convert under-exploited mineral wool into sustainable raw materials for the construction industry.

- The Innovation: Using Alkali-activation (Geopolymerization) to turn the reactive silica and alumina in wool into a binder, replacing CO2-intensive Ordinary Portland Cement (OPC).

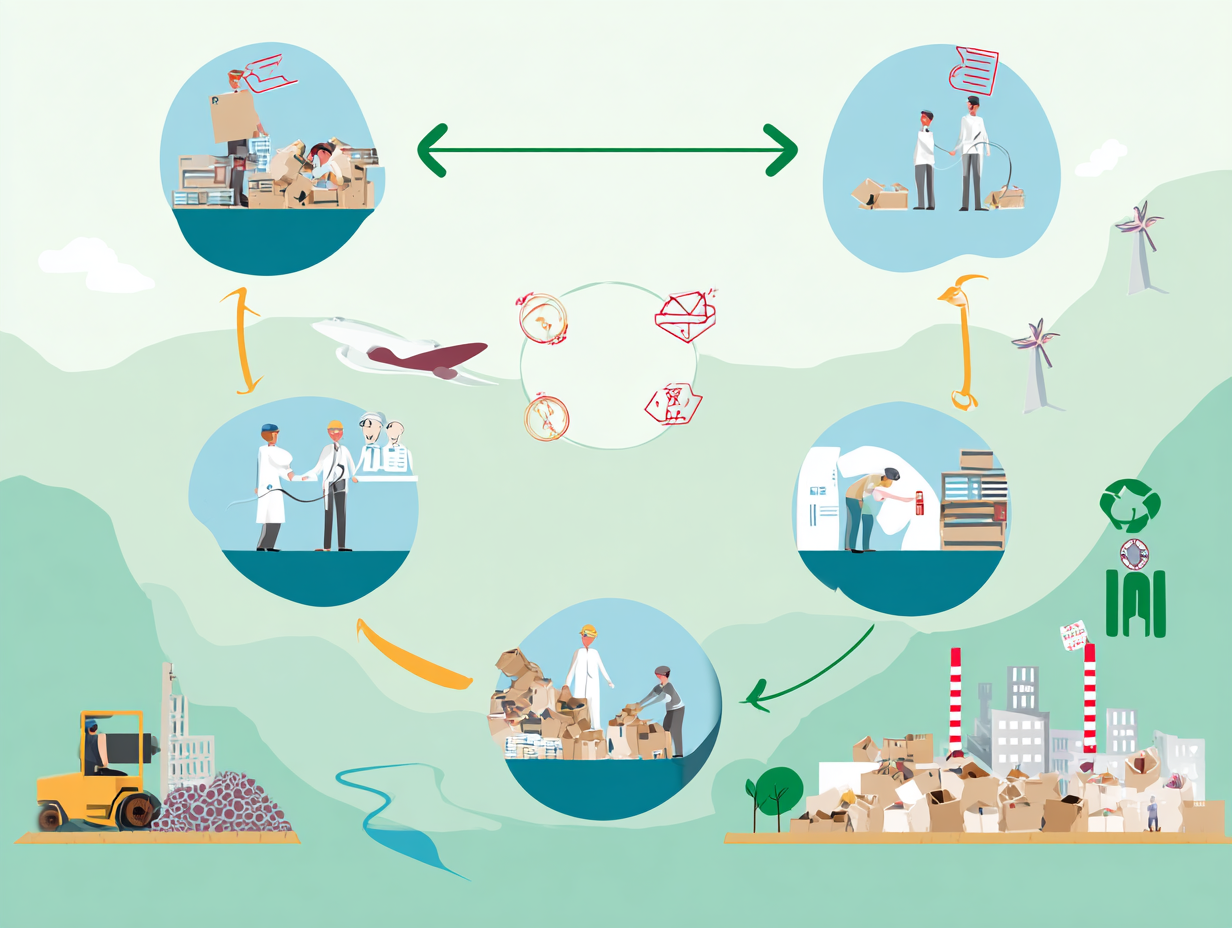

- The Circular Loop: Spans from pre-demolition audits and robotized demolition to smart sorting and final product manufacturing.

Key Performance Indicators (KPIs) & Results

The project successfully demonstrated that mineral wool is a viable secondary raw material at an industrial scale.

| KPI Category | Achievement |

| Intellectual Property | 6 Patent applications filed |

| Scientific Output | 17 Peer-reviewed articles (8 published, 9 in progress) |

| Consortium Scope | 14 Partners across 9 EU countries |

| Material Diversion | Potential to unlock 2.5 Mt/year of mineral wool for reuse |

| Product Prototypes | 5 unique product types produced in large-scale pilots |

| Funding/Business | Industrial partners are already investing in up-scaling the concept |

Main Deliverables & Work Performed

The project moved through the entire value chain to prove the feasibility of the circular concept:

1. Smart Demolition & Sorting

- On-site Analysis: Utilized time-gated Raman spectroscopy and handheld XRF technology to identify material composition before demolition.

- Audit Guidelines: Created standardized procedures for pre-demolition audits involving mineral wool.

2. Pre-treatment Technologies

- Processing: Developed systems for compression, shredding, and ball milling to achieve the specific particle size required for geopolymerization.

- Environmental Safety: Successfully managed risks related to organic resin content and ammonia emissions during the activation process.

3. Novel Construction Products

Large-scale pilots produced a variety of AAM (Alkali-Activated Material) products:

- Precast Elements: Pavement slabs, facade elements, and reinforced wall panels.

- Acoustic Panels: Utilizing the inherent properties of the original wool.

- Dry Mixes: Floor screed and 3D-printing concrete materials.

Impact & Policy Recommendations

WOOL2LOOP positioned itself as a key contributor to the EU Green Deal and the Paris Agreement by decoupling economic activity from resource depletion.

Key Barriers Identified

Despite the success, the project highlighted five hurdles for market uptake:

- Shortage of traditional slag/binders.

- Lack of collection infrastructure for secondary raw materials.

- Outdated building codes.

- High investment costs for upscaling.

- Market conservatism toward non-OPC concrete.

Policy Recommendations

- Taxation: Implement taxes on virgin materials or landfilling to make “wasterials” more competitive.

- Performance Standards: Shift building codes from “material-based” to “performance-based” to allow for new low-carbon cements.

- Green Procurement: Encourage public bodies to require LCA (Life Cycle Assessment) data for all building products.