CEWASTE project (2018–2021)

Grant agreement ID: 820859

DOI

Project closed

EC signature date3 October 2018

Start date1 November 2018

End date30 April 2021

This summary captures the outcomes of the CEWASTE project (2018–2021), which tackled one of the most difficult challenges in the circular economy: the recovery of Critical Raw Materials (CRMs) from electronic waste and batteries.

Context & Strategic Objectives

Europe is heavily dependent on foreign supplies for CRMs (like lithium, cobalt, and rare earth elements) essential for high-tech and green industries. While recycling is a solution, CRM recycling rates are currently near zero because it is technically difficult and economically unattractive.

- The Problem: Low and volatile prices for CRMs make the necessary high-capital recycling technologies risky for private firms.

- The Solution: A Voluntary Certification Scheme to ensure traceable, sustainable, and high-quality treatment of CRM-rich waste across the entire supply chain.

- Target Waste: Waste Electrical and Electronic Equipment (WEEE) and waste batteries from both consumer electronics and End-of-Life Vehicles (ELVs).

Key Results & Technical Achievements

CEWASTE moved beyond existing general recycling standards to create specific, technical requirements for the recovery of 14 categories of Key CRM Equipment (KCE).

| KPI Category | Achievement |

| KCE Identification | 14 categories of waste identified with high CRM concentrations and feasible recovery tech. |

| Normative Gap | Mapped 60+ existing requirements, finding a total lack of technical standards for CRM recovery. |

| Validation | 20 pilot audits conducted globally (EU, Colombia, Rwanda, Turkey). |

| Operational Tools | Developed an Audit Checklist and assurance framework for facility certification. |

| Sustainability | Created a Long-term Roadmap for the business viability of CRM recovery. |

Main Deliverables & The Certification Scheme

1. The Normative Requirements

CEWASTE built upon the CENELEC EN 50625 standard series. While previous standards focused on general depollution, CEWASTE added specific requirements for:

- Environmental & Social Performance: Ensuring “urban mining” doesn’t harm workers or the planet.

- Technical Performance: Specific mandates on how to identify and handle CRM-rich components (e.g., printed circuit boards, magnets).

2. The Pilot Audits

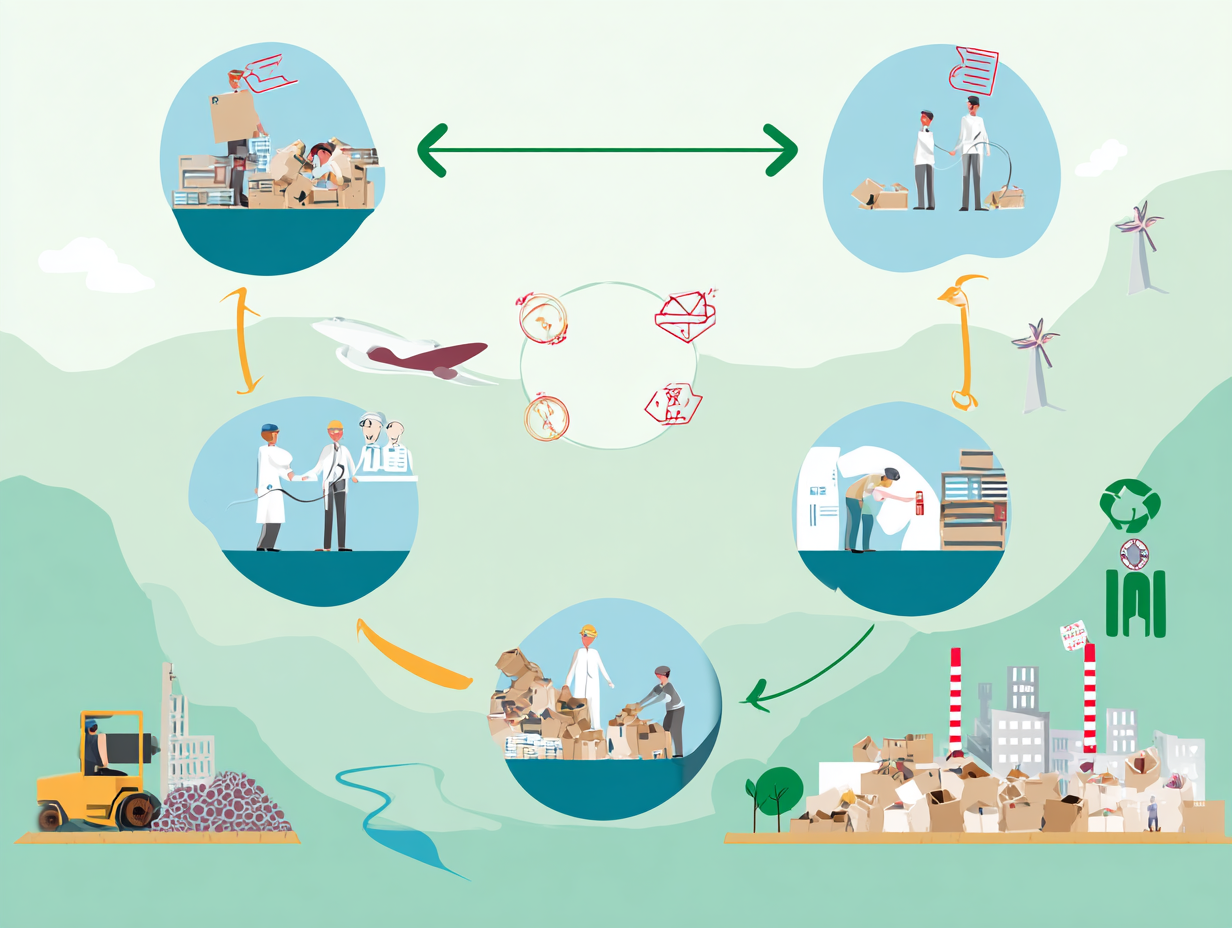

To prove the scheme worked in the “real world,” audits were performed across the entire value chain—from collection and transport to specialized treatment facilities. This validated that the standards were practical for both small operators and large industrial recyclers.

3. The CRM Roadmap

The project identified that technical standards alone aren’t enough. The roadmap suggests “clustering”—where Producer Responsibility Organizations (PROs) consolidate small amounts of CRM-rich waste into large enough batches to make industrial recycling profitable.

Socio-Economic & Policy Impact

The legacy of CEWASTE is the creation of a “level playing field” where high-performing recyclers are rewarded for recovering difficult materials.

- Market Stabilization: By identifying best practices, the scheme creates a favorable environment for long-term investment in recovery technologies.

- Security of Supply: Increased recovery rates reduce the EU’s vulnerability to global supply chain disruptions of rare metals.

- Fair Competition: Standardized rules prevent “leakage” of valuable materials to sub-standard facilities or illegal transboundary shipments.

Key Policy Recommendations

The project concluded that the responsibility for CRMs is a shared societal challenge, requiring specific legislative actions:

- Mandatory Integration: Integrating CEWASTE requirements into the EN 50625 series and making them legally binding.

- Market Incentives: Using fiscal tools to make secondary (recycled) CRMs as cheap or cheaper than virgin materials.

- Traceability: Ensuring all actors have access to information on which components contain CRMs to make monitoring easier.