The ECO-CEMENT project developed a sustainable cement alternative using bacteria to precipitate calcium carbonate through urea hydrolysis, reducing carbon emissions and utilizing industrial wastes.

Project Overview

This EU-funded initiative (around 2012-2014) aimed to create eco-friendly cement by mimicking natural microbial processes, targeting reductions in greenhouse gases by 11%, construction waste by 20%, and production costs by 21%. It focused on revalorizing waste streams like cement kiln dust (for calcium), biological wastes (for urea), and dairy wastes (for nutrients). The process avoids traditional cement’s high-energy kiln firing, which contributes about 5% to global CO2 emissions.

Bacterial Process

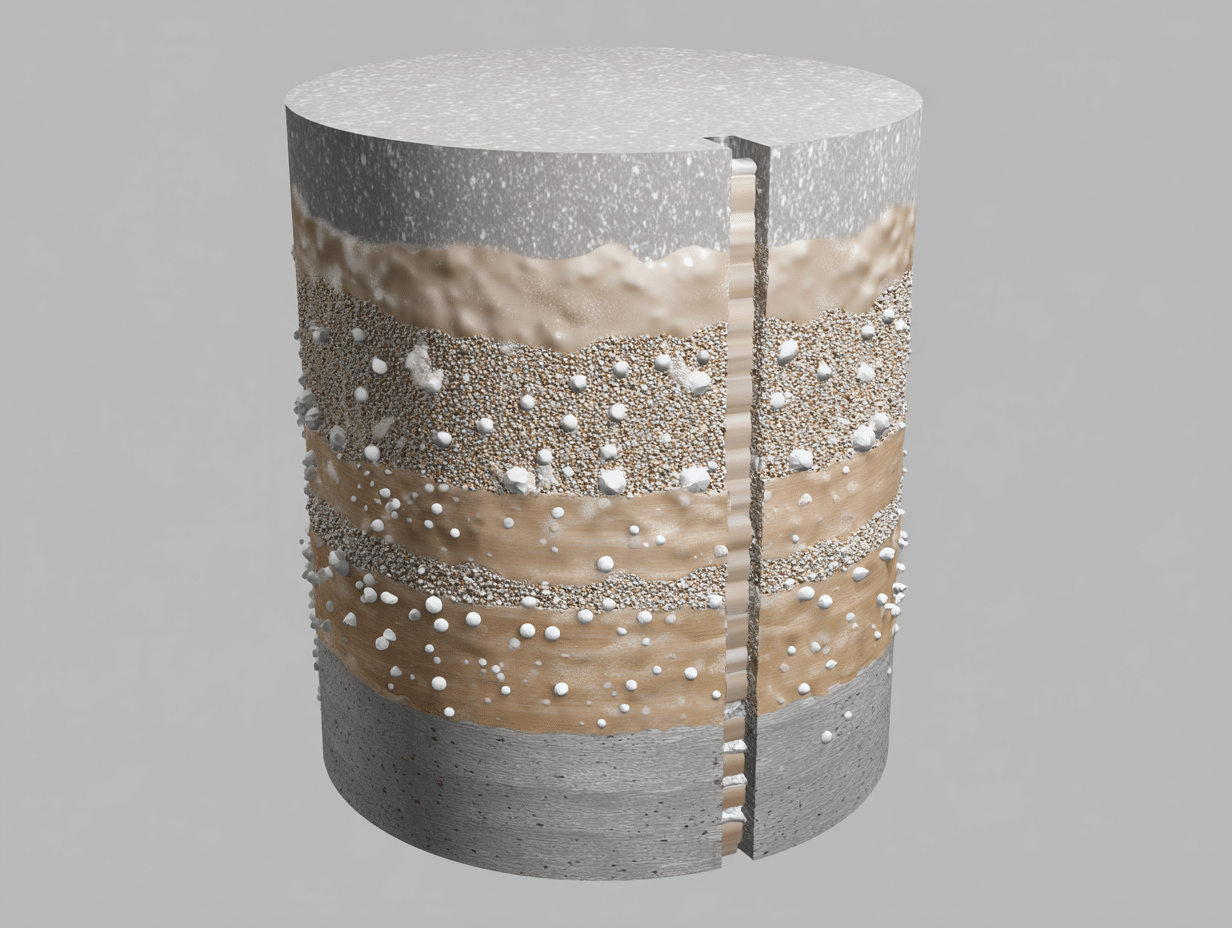

Sporosarcina pasteurii was selected as the key bacterium due to its high urease activity, calcite precipitation rate (up to 100% efficiency at 3-4 mg/mL Ca2+), and resilience to harsh conditions like cement kiln dust. The bacteria hydrolyze urea into ammonia and CO2, forming carbonate ions that bind with calcium to create crystalline calcite, which acts as a cement binder when mixed with aggregates like sand or rice husk ash. Tests showed improved hardness (e.g., Shore A of 64 vs. 54 for controls) and potential applications in tiles, plasters, mortars, and self-healing materials.

Outcomes and Impact

Life-cycle assessments confirmed superior sustainability over Portland cement, with pilot trials validating strength and scalability. The project proposed dry bacterial inoculants for easy on-site use and anticipated 2,000 jobs in Europe. While not yet mainstream, it inspired ongoing bacterial concrete research for self-healing and low-carbon builds.